Atoms In Use from Start to Finish

Monitor Critical Mining Equipment

Equipment Types and Monitoring Needs

Screens and Shakers

- Bearing Temperature

- Vibration

- Impact

- Runtime

Conveyors/Elevators

- Motor Operation

- Bearing Temperature

- Vibration

- Impact

Crushers

- Motor Operation

- Vibration

- Bearing Temperature

Dryers

- Bearing Temperature

- Vibration

- Impact

Equipment Maintenance Monitoring

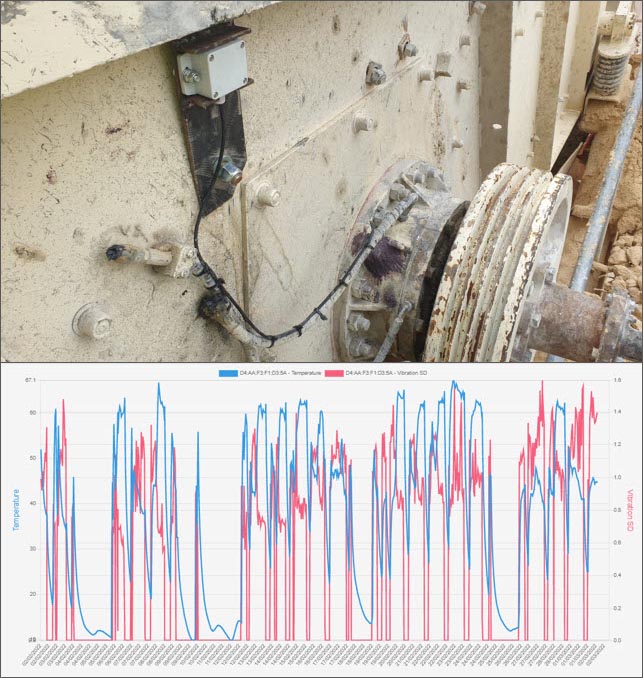

Multiple Atoms are in use in this production step. AT-R1.0 Atoms, connected via Bluetooth to our gateway, are attached to the shaker tables to monitor vibration and impact. An augmented Atom with an external temperature sensor monitors the bearing temperature of the motor. These Atoms provide a detailed view of shaker table performance and deliver alerts when the shakers need attention:

- Bearing Health: bearing temperature increases may signify over-lubrication. Real-time alerts in temperature increase above threshold give operators the opportunity to intervene before failure or damage occurs.

- Screen Health: vibration changes alert operators to screen and motor degradation before the equipment fails, giving operators the opportunity to schedule maintenance, replace critical parts of re-route materials, preventing downtime and equipment failure during operation.

Productivity Management

Delivering on ROI

The Atomation platform delivers positive ROI quickly. The cost of an Atom is significantly lower than the labor costs involved in periodic monitoring, including the current time invested when employees use a hand-held gun to determine temperature. Add that Atoms continuously monitor equipment for issues that may arise, giving teams the opportunity to proactively manage equipment and prevent downtime, and the solution delivers positive ROI almost from day one.

- Continuously monitor all critical equipment – regardless of location – and receive alerts when equipment requires attention

- Reduce labor costs incurred when doing manual temperature and machinery checks

How can Atoms transform your operation?

Schedule a demo today and let’s work together to see where Atoms can best assist your efforts to improve your operations.